Cost is one of the ‘Golden Triangle’ of a construction project. Even before the project is being detailed out in the initial stages, cost holds as one of the major success factors of a project. Therefore, it is vital to handle it carefully. In a total of project cost, the cost of mechanical and electrical (M&E) works can be in a range of 20-40%, depending on the functions of the asset. Question of the day, how do these costs are being determined? It is often seen as a ‘grey area’ for project stakeholders when it comes to the detailed cost of M&E works. However, the procedures of managing the cost of M&E works are not so complexed if we adopt the right cost model and strategy.

Cost Estimation Process of M&E

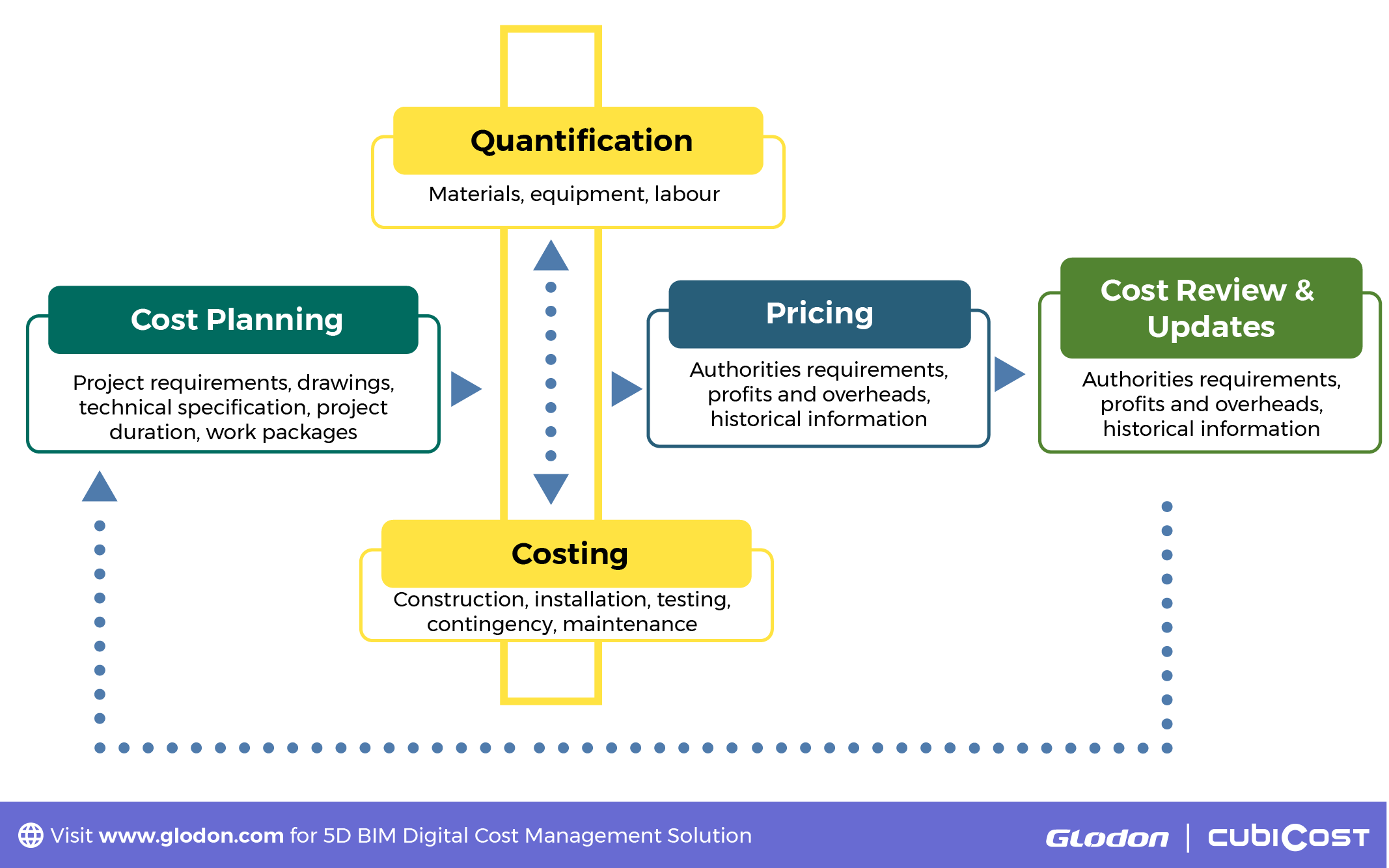

So, how the process of M&E cost estimation is being carried out? To start with, the estimation is not only referring to the set of project drawings but also depends on the information stated on the technical data and specifications. Besides the type of material, detailed specifications of equipment and method of installation must also be understood to ensure the accuracy of cost estimate.

To administer that systematically, the M&E works are separated into several elements. For example, in a typical building project, under mechanical, there are cold water and sanitary plumbing system, fire detection and protection system, air-conditioning and mechanical ventilation system. Meanwhile, under electrical, there are medium and low voltage system, lighting and small power system, earthing and lightning system, and extra-low voltage system. The systems are breakdown into smaller items comprise of the materials and equipment, installation parts, labour, profit and overheads to yield the overall cost of the works.

Standard Method of Measurement

Typical for a construction project in Malaysia that the M&E bills of quantities are prepared by the M&E engineers. Somehow, it collides with the engineer’s main responsibilities, which more focused on the design, engineering, and coordination works. It can be found that the application of the local standard method of measurement is almost non-existent in Malaysia. Most of the M&E firms are more inclined towards the use of their standards in preparing the bills of quantities.

The lack of understanding of the standard method of measurement for M&E works has to be the main reason why lump sum contracts are often being used in the industry. The potential of unfair agreement, higher cost of project, and difficulty to analyse and assess the cost due to design change are among the disadvantages of using this type of contract. In establishing reliable project quantities and costing of M&E works, it is important to adopt a recognised standard for measurement or taking-off process.

In Malaysia, we have Standard Method of Measurement 2 (SMM2) and the latest, Malaysian Standard Method of Measurement (MySMM) for Building Works. Internationally, New Rules of Measurement (NRM 2) by the Royal Institution of Chartered Surveyors (RICS) are getting more popular even in the Southeast Asian countries. However, more initiative has to be taken by many parties especially the academic institutions in promoting the usage of these standard methods of measurements for the M&E works in Malaysia.

Changing Trends – Preference Towards QS Background

In terms of career development, it is noticed that the trends of M&E consultancy firms and contractors start hiring people with a quantity surveying background to handle contract and commercial matters. Different from 10 years ago, where the commercial matters were dominated by those with an engineering background.

Despite the inclination towards quantity surveyor, it is urged that those with interest in specialising in M&E must be open to learning about the technical aspects of it, which include the understanding of M&E design process, project specification, as well as how the coordination and installation works are being carried out. This will help a quantity surveyor to deliver more accurate costing and aware of making a decision that can influence the risks related to contract and commercial.

A quantity surveyor is the most competent person to handle the measurement works and cost. In the university, they are trained to be precise and more aware of any contractual matter that can jeopardise the objectives of a project. As they are already proven to be capable of handling the matters for civil, structural, and architectural works in the industry. With proper training and exposure, the client can expect the same outcomes for M&E works from quantity surveyors in Malaysia.

The Prospect of M&E QS and Future Practice of Quantity Surveying

The M&E areas are hugely undervalued in this country. It is very rare to see the quantity surveying firms are offering their service to handle the scope of M&E works. Different from other countries in the region. Take an example of Philippines, an M&E QS can be found in almost all the quantity surveying firms. This trend can also happen in Malaysia if we take the right approach to promote the M&E QS profession in the country.

To go beyond, quantity surveyor also needs to have the capability to estimate the life-cycle cost of an asset through the best selection of design, material, and equipment, which is part of the value engineering process. This involves the capacity to make a future asset operating at optimal cost, offer long-term savings, and high return on investment.

Understanding the risks of the installation and coordination works at a construction site that can influence the project cost will also make the presence of M&E QS to be significantly important. Various software and advanced technologies are growingly being applied in the industry. Therefore, quantity surveying practice is also needed to grow steadily along with the development in the industry.

With more capabilities in quantity surveying practice, it can help to boost the competency and value of quantity surveyors in Malaysia. It is also hoped that many quantity surveyors to start adopting the use of software applications and explore the potentials of Building Information Modelling (BIM) in practice as this aligns with the Construction 4.0 agenda established by the Construction Industry Development Board (CIDB) Malaysia in their recent 2021-2025 Strategic Plan.