In the middle of February, the renovation work of Xiaotangshan Hospital has been finished. It only took 10 days. Xiaotangshan Hospital was built to treated patients when China has experienced SARS in 2013. It was reused under Covid-19 to cope with the possible shortage of medical resources caused by the epidemic.

This 430 million-square-foot makeshift medical facility is planned to receive international arrivals for further screening, quarantine, and treatment of mild cases of novel coronavirus disease (COVID-19). Pictures of the construction on social media show dozens of bulldozers and excavators rushing to level the ground. It just takes several days, an almost new hospital has started to house patients.

How China call the resources and finished building in such few days? How did private third parties help the project? You might find the answer below.

“Smart-Site” has largely accelerated the process

The tensing time is the first problem to be solved. Although it is only renovation and repair, it involves a large number of new engineering equipment, including new ventilation system, weak current system, fresh air system, negative pressure system, VRV air-conditioning system, calling system, oxygen supply system and many different types of work.

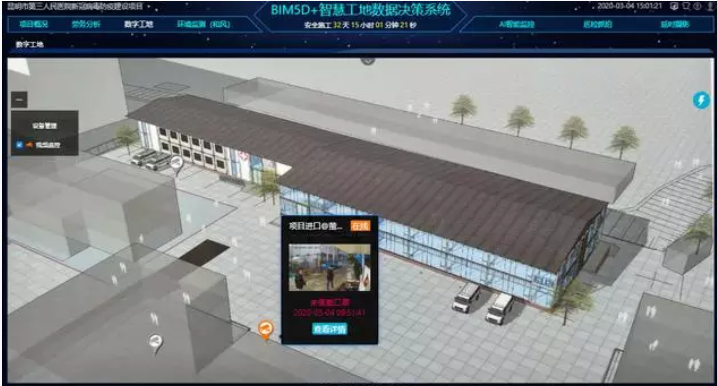

BIM Smart Site System of Glodon

BIM Smart Site System of Glodon

To ensure complete isolation between doctors and patients, double channels were expected to be added. In less than 30 square meters, the patient room was segmented by doors from one to four to ensure the safety of medical staff and patients.

This large project is collectively delegated to institutions in multiple companies. As one of them, Beijing Construction Engineering Group is mainly responsible for zone B, zone E and zone north (1500 beds). In just three days, the project management team and over 5,000 workers arrived on site and began to work.

Instead of labor resources, another main challenge is to find the best way to work effectively. In this case, it is essential to use the efficiently software. As the corporation partner of Beijing Construction Engineering Group, Glodon Company Limited (Glodon) use their products to help accelerate the process.

Smart site data gathering system of Glodon

Smart site data gathering system of Glodon

The project utilizes the BIM5D + smart site data decision system to integrate the application of the construction site and manage the hardware equipment with the unified BI platform. On the BI system, the project management department can do real-time checking of the site situation, including the number of present workers, the potential risks on-site and the violations that need to be corrected, etc.

Safety of the workers decides the success of the project

The safety of the workers are important as well. In labor-intensive settings, the epidemic outbreaks are easy to happen, which means any omission of detail can cause delay in progress. The software of Glodon have perfectly solved the problem, which are the software system of the real-name system of labor service and thermal imaging human body temperature measurement system.

The workers in line

The workers in line

As one of the Glodon's labor service, a real-name software "Kuai Deng Bao" implements the real-name registration system. The purpose is to alert high-risk workers from affected areas. The face recognition function can ensure that external individual are not allowed to enter the construction site. Meanwhile, the real-time monitoring can collect relevant personnel information to guarantee the safety of the migrant workers.

Dashboard of data system

Dashboard of data system

To better manage the workers in a relatively low cost, the thermal imaging human body temperature measurement system is installed at the entrance and exit of the site. The management cost can be saved largely through this system as the infrared non-contact body temperature detection is used to reduce the risk of cross-infection. Besides, it can realize the rapid simultaneous temperature detection and screening of multiple people at a relatively long distance and large area. It also can detect hypothermia patients. The equipment can automatically identify and warn them so to prevent the spread of the epidemic.

By smartly using digital tools on-site, the repairing efficiency are improved largely. The hospital is renovated in just a few days with all the possibility risks are considered before. "You want your construction site to be as low-risk as possible," a project manager explained. "For the building progress you want the workers to be completely protected, because 'people' are always the key to the project success."